Questions: Why Do RIP-R-SRIPPER® Products use

Allen Head-Type Capscrews to Clamp the Blade?

Answer: To Minimize being Cut by the Sharp Blade.

RIP-R-STRIPPER® blades are manufactured from special, high carbon steel, heat treated for longer service life and then ground to produce an extremely sharp edge that maximize cutting efficiencies in a wide variety of covering materials and adhesives.

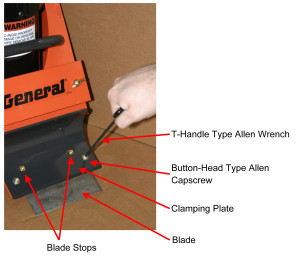

- The Button-Head, Allen-type capscrews and a long T-handled-type Allen wrench keep the hand and other body parts clear of the sharp blade edge.

- Allen-type capscrews are classified as Grade 8, the strongest type of capscrew available for this application.

- The rounded, button-head configuration is intended to help lose materials to better flow up and around the Clamping Plate.

Need help?

Call us at 800.533.0524, or

email: support@generalequip.com.

When the original factory Bottom-Head, Allen-type capscrews become worn, damaged, or lost, replace with Part Number 55050600 (5/16-18 UNC x ¾” long, plated) ONLY.

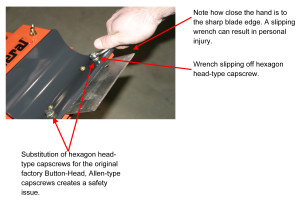

The substitution of hexagon head-type capscrews will place the hand and other body parts in close

proximity to the sharp blade edge. A slipping wrench can result in personal injury and property

damage.

- Grade 2 and 5 capscrews are not as strong as Grade 8, Allen-type capscrews.

- The use of hexagon head-type capscrews will prevent lose materials from properly flowing up and around the Clamping Plate.

- A combination wrench can slip off the hex head capscrew and cause personal injury.

If you have any questions or comments, please feel free to contact us.

Telephone: 800.533.0524 | Email: support@generalequip.com