New Changes in Two Man Auger Bits

For 2014, there are changes in the bits that utilized with the General 330H Two Man Auger. These are the first significant change in the bit boring head design in over 50 years! This is an update to help provide further information to correctly order replacement parts.

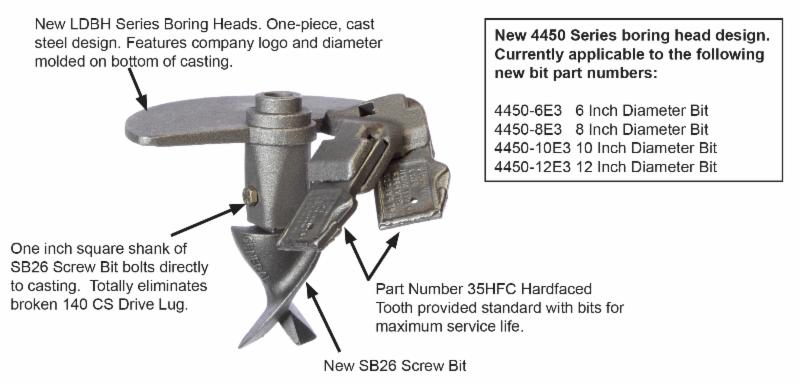

New 4450 Series bits incorporate the following changes:

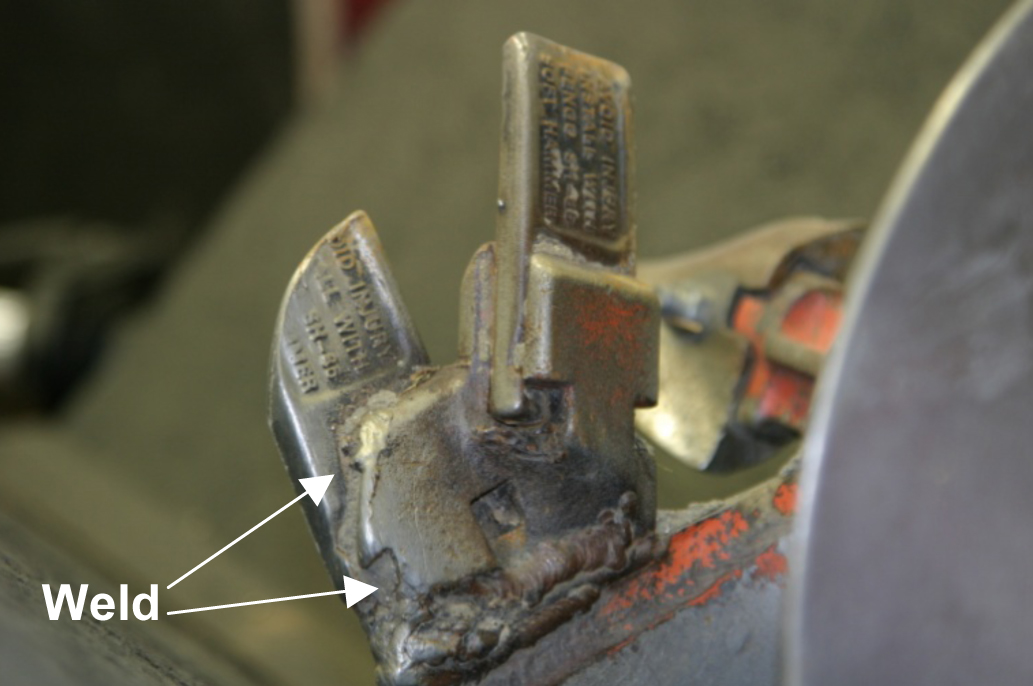

- Eliminates the 140CS Drive Lug.

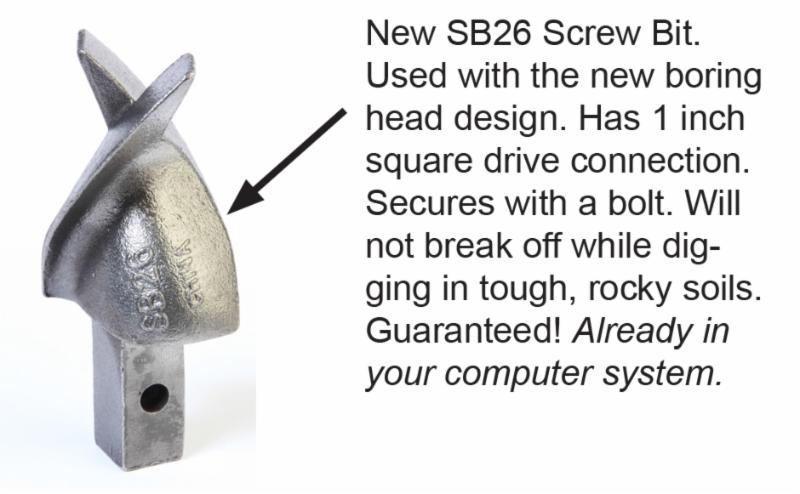

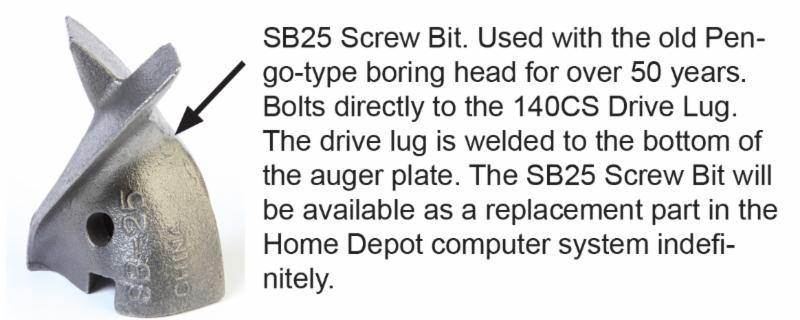

- Replaces the SB25 Screw Bit with the new SB26 Screw Bit. The SB26 Screw Bit design eliminates any potential breakage from the 140CS Drive Lug.

- Features a one piece, steel casting assembly with the specific bit diameter and General logo molded into it.

- Sophisticated software was used to optimize tooth angle and position.

- The new design better allows the bit to be more easily robotically welded. Robotic welding will increase manufacturing consistency and quality.

So…what’s the big deal? A bit is a bit. Right?

Well, the big deal is this: General is doing something different to manufacture a bit that digs better and lasts longer. The new 4450 Series bits are available in popular sizes: 6, 8, 10 and 12 inch diameter. Look for them beginning in February!

Need help?

Call us at 800.533.0524, or

email: support@generalequip.com.

Replacement wear part numbers for the 4450 Series Bits are as follows:

- Teeth: Part Number 35HFC

- Screw Bit: Part Number SB26

- Bit Connecting Pin: Part Number 2121

Bit Part Number Information:

- New 4450-6E3 6 Inch Diameter, Replaces 4400-6E3

- New 4450-8E3 8 Inch Diameter, Replaces 4400-8E3

- New 4450-10E3 10 Inch Diameter, Replaces 4400-10E3

- New 4450-12E3 12 Inch Diameter, Replaces 4400-12E3

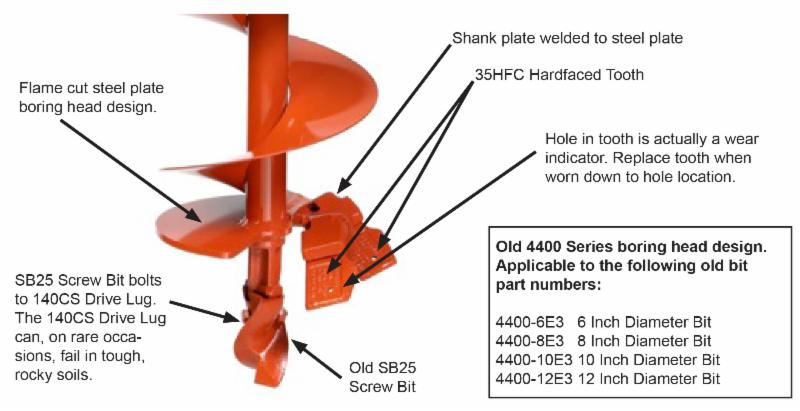

Screw Bit Design Comparison

New 4450 Series Bits

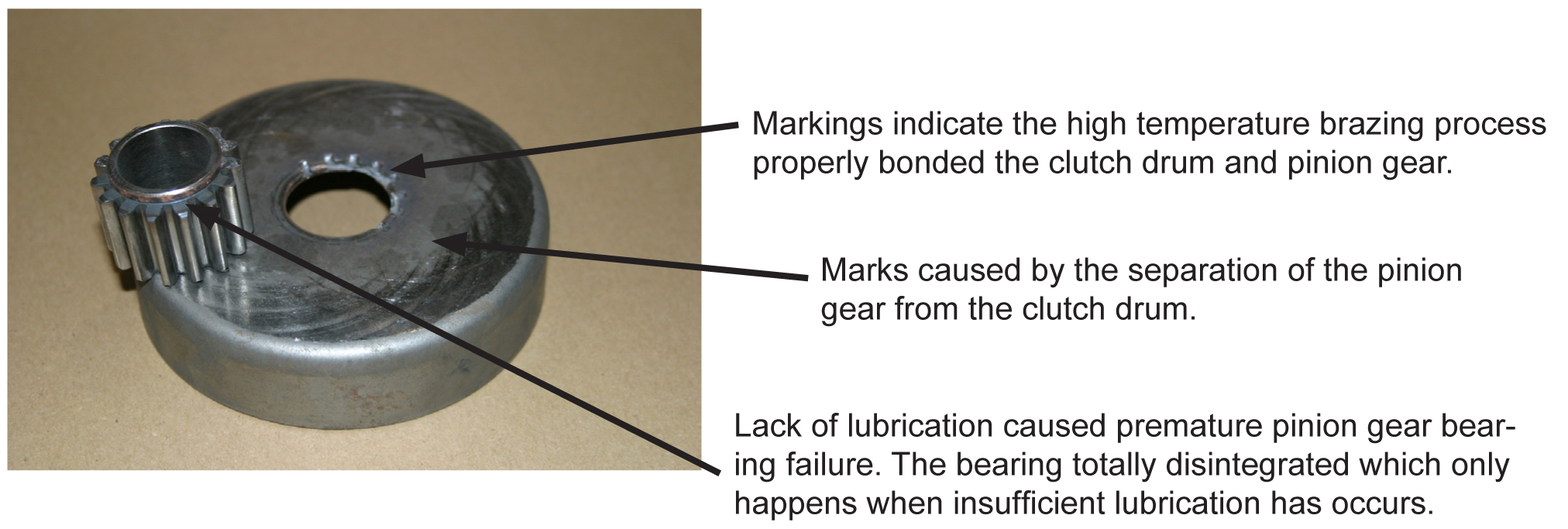

Old 4400 Series Bits

If you have any questions or comments, please feel free to contact us.

Telephone: 800.533.0524 | Email: support@generalequip.com